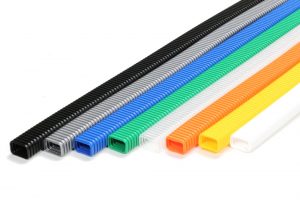

Case studies of wiring flexible tube introduction

Company T manufactures various control boards and distribution boards. The company received an order for a mass-produced product, and while considering the reduction of work man-hours, examined production using our wiring flexible tube.

Company T manufactures various control boards and distribution boards. The company received an order for a mass-produced product, and while considering the reduction of work man-hours, examined production using our wiring flexible tube.

With conventional construction methods, it is necessary to install the wires in an L shape and bind and fix them with a binding band or use a wiring duct. However, with the flexible tube, work can be complete simply by inserting the wires in the tube on the workbench and mounting them in pre-installed fixtures. As a result of this Company T was pleased to report that a significant reduction in man-hours was achieved.

In addition, introduction of the wiring flexible tube led to scratch prevention and appearance improvement by eliminating exposure of the electric wires.

Wiring flexible tube introduction flow

- Conventional construction methods require many man-hours. Reduction of man-hours and increase in production efficiency are necessary for a mass production model.

- Exposure of the electric wires should be minimized.

- Proposal of products that will reduce man-hours

- Since the wires only need to be inserted into the tube on the workbench and attached to the pre-installed fixtures, it became possible to drastically reduce work man-hours compared with conventional methods.

- Measurement and cutting work of the ducts became unnecessary

- The task of binding and fixing in the binding band became unnecessary