Case studies of wiring flexible tube introduction

Company S is a manufacturer of various manufacturing equipment for sanitary products, etc. They became interested in wiring flexible tubes after seeing the products at Kowa Kasei’s booth at an exhibition.

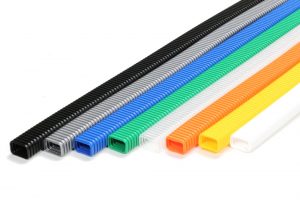

There was a place where wiring was fixed with binding bands along an aluminum frame. By using this product, it became possible to improve workability and protect the electric wires, and by using a silver color type similar to the aluminum frame, the appearance of the equipment improved. Company S is very pleased with these benefits.

In addition, with eight color variations, their customer was very pleased that they could use different colored tubes by system or use their corporate colors, improving appearance.

Wiring flexible tube introduction flow

Issues before introduction

- Worry about places where the wires were exposed

- It is not possible to wire cleanly with a round tube for planar wiring

- Wiring work without spending time

- Color variation is necessary to handle color coded wiring, etc.

Requests

- Rectangular shapes for planar wiring

- Variations other than black in order to handle the color coded wiring system

Achievements / Improvements

- Improved fit of aluminum frame and tube when used with fixing tool! Planar wiring became easier due to the rectangular shape.

- Circuit division can be supported with eight color variations

- Improvements in appearance and customer satisfaction