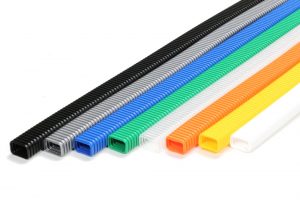

Case studies of wiring flexible tube introduction

Company M is a global company that provides a wide range of building materials and equipment for detached houses and apartments, offices, commercial facilities, etc, and a wide range of services.

Company M is a global company that provides a wide range of building materials and equipment for detached houses and apartments, offices, commercial facilities, etc, and a wide range of services.

They decided to adopt the wiring flexible tube inside their own factory. The purpose of use is to accommodate cables such as for soldering irons and electric screwdrivers which are mounted on the cell production workbench.

Company M is pleased that wiring protection and improvement of appearance were achieved by using this product. Regarding improvement of appearance in particular, Company M is pleased to report that 2S improvement was achieved in the factory by eliminating exposed wires because there were many opportunities for customers to come on factory tours. Company M continues to consider prospects for further 2S improvement in the factory.

Wiring flexible tube introduction flow

- The appearance of the electric wires around the workbenches gives bad impression to customers who come on factory tours.

- Wires are not protected around the workbenches for cell production

- It takes time and effort to cut off the bands that bind the wires when a new line setup is made.

- Make the electric wires less noticeable with tubes of the same color as the cell production workbenches

- Realize cable protection for various tools

- Make it easier to start a new line

- Improved appearance around the workbenches by using silver color

- Use of the product realizes wire protection

- Suitable for wiring between steps or bent wiring, etc., shortening the time required to set up new lines

- Using a tube with a slit type makes it easy to store the tool cable even as a retrofit